Founded in 1991, ZY Zipper Machinery is a One-stop Solution Provider of zipper machines for Bag & Apparel Zipper Production.

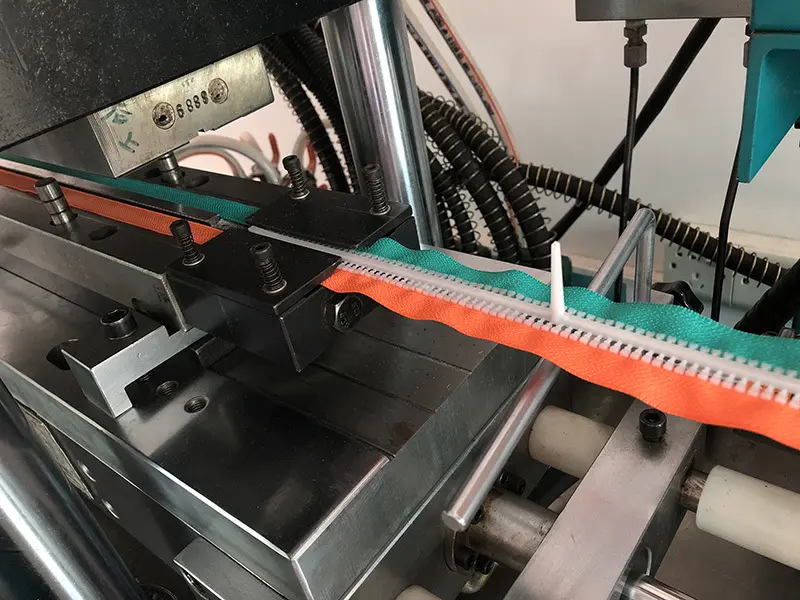

ZYZM semi automatic plastic injection moulding machine Suppliers for zipper manufacturer

PRODUCT FEATURES

bg

- 01Produce symmetrical teeth & normal teeth

- 02Easy to use and operate

- 03Widely used in kids apparel zipper,adults up dress like jacket

- 04Suitable for difernent zipper size from #3 ~#20

- 05with PC automatic control program

- 06Installation, training and after-sales service are available

PRODUCT CHARACTERISTIC

bg

Teeth injection mold

Finished look for normal teeth zipper

Finished look for special teeth zipper

TECHNICAL SPECIFICATION

bg

| Style Number | ZY-601R |

| Machine Name | Fully auto plastic zipper injection molding machine(derlin teeth injected machine) |

| Capicity | 300Y/H |

| Size | #3, #4, #5, #7, #8, #10, #15, #20 |

| Power | 9.00KW |

| Voltage | 380V |

| Machine Measurement (M) | 3.00*0.70*2.76 |

| Net Weight | 900KG |

| Warranty | 1 year |

| After-sales service | Available |

{{scoreAvg}}

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

Quick links

Contact ZY Zipper Machinery

Contact Person: Tammy Kuo

Tel: +86-020-66260710

Phone/Whatsapp: +8613632249532

E-Mail: tammy@zyzm.com

Add.: 6 Daxin Road, LiCheng, ZengCheng District, GuangZhou City, GuangDong Province China

Copyright © 2025 Zhenyu Zipper Machines Co.,Ltd. - www.zipper-machines.com | Sitemap | Privacy Policy

Contact us

Leave your inquiry, we will provide you with quality products and services!

Customer service