ZYZM plastic injection moulding machine Supply for molded zipper production

Company Advantages

1. In order to shore up the position of ZYZM, it is also necessary to design plastic injection moulding machine .

2. This kind of product can easily accomplish the arduous work that people can't do. This will undoubtedly increase productivity and ease the pressure on workers.

3. It offers the demanded elasticity. It can respond to the pressure, evenly distributing body weight. It then returns to its original shape once the pressure is removed.

4. The product is helpful in keeping the drains working. It is designed to pull out or remove any debris that may land in the water.

5. This product has the desired safety and security. Not only the housing is made of high insulation materials, but also the metals electric parts are professionally encapsulated to prevent any leakage.

![ZYZM plastic injection moulding machine Supply for molded zipper production 7]()

![ZYZM plastic injection moulding machine Supply for molded zipper production 8]()

![ZYZM plastic injection moulding machine Supply for molded zipper production 9]()

Company Features

1. Zhenyu Zipper Machines Co.,Ltd integrates the design, production, sales and service of plastic injection moulding machine . Almost all technician talent for the industry of best plastic injection moulding machine work in our Zhenyu Zipper Machines Co.,Ltd.

2. Our technology is always one step ahead than other companies for plastic injection machine .

3. Our advanced machine is able to fabricate such small plastic injection molding machine with features of [拓展关键词/特点]. Zhenyu Zipper Machines Co.,Ltd persists in the service theory. Get info!

1. In order to shore up the position of ZYZM, it is also necessary to design plastic injection moulding machine .

2. This kind of product can easily accomplish the arduous work that people can't do. This will undoubtedly increase productivity and ease the pressure on workers.

3. It offers the demanded elasticity. It can respond to the pressure, evenly distributing body weight. It then returns to its original shape once the pressure is removed.

4. The product is helpful in keeping the drains working. It is designed to pull out or remove any debris that may land in the water.

5. This product has the desired safety and security. Not only the housing is made of high insulation materials, but also the metals electric parts are professionally encapsulated to prevent any leakage.

PRODUCT FEATURES

bg

PRODUCT CHARACTERISTIC

bg

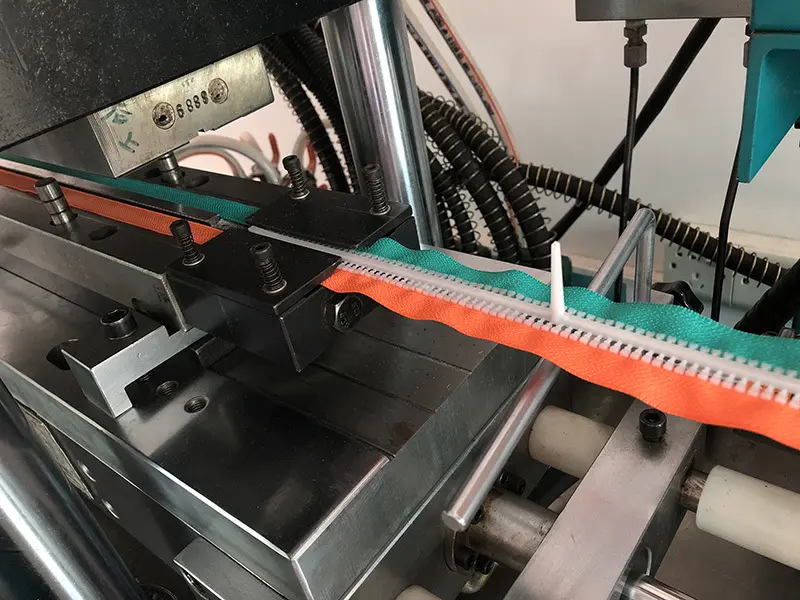

Teeth injection mold

Finished look for normal teeth zipper

Finished look for special teeth zipper

TECHNICAL SPECIFICATION

bg

| Style Number | ZY-601R |

| Machine Name | Fully auto plastic zipper injection molding machine(derlin teeth injected machine) |

| Capicity | 300Y/H |

| Size | #3, #4, #5, #7, #8, #10, #15, #20 |

| Power | 9.00KW |

| Voltage | 380V |

| Machine Measurement (M) | 3.00*0.70*2.76 |

| Net Weight | 900KG |

| Warranty | 1 year |

| After-sales service | Available |

Company Features

1. Zhenyu Zipper Machines Co.,Ltd integrates the design, production, sales and service of plastic injection moulding machine . Almost all technician talent for the industry of best plastic injection moulding machine work in our Zhenyu Zipper Machines Co.,Ltd.

2. Our technology is always one step ahead than other companies for plastic injection machine .

3. Our advanced machine is able to fabricate such small plastic injection molding machine with features of [拓展关键词/特点]. Zhenyu Zipper Machines Co.,Ltd persists in the service theory. Get info!

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

Quick links

Zipper machine products

Contact ZY Zipper Machinery

Contact Person: Tammy Kuo

Tel: +86-020-66260710

Phone/Whatsapp: +8613632249532

E-Mail: tammy@zyzm.com

Add.: 6 Daxin Road, LiCheng, ZengCheng District, GuangZhou City, GuangDong Province China

Copyright © 2025 Zhenyu Zipper Machines Co.,Ltd. - www.zipper-machines.com | Sitemap | Privacy Policy