ZYZM Zipper Machine Manufacturer-One Stop Solution Service Provider for all kind of Zipper Making Machines.

ZYZM Zipper Machine Manufacturer-One Stop Solution Service Provider for all kind of Zipper Making Machines.

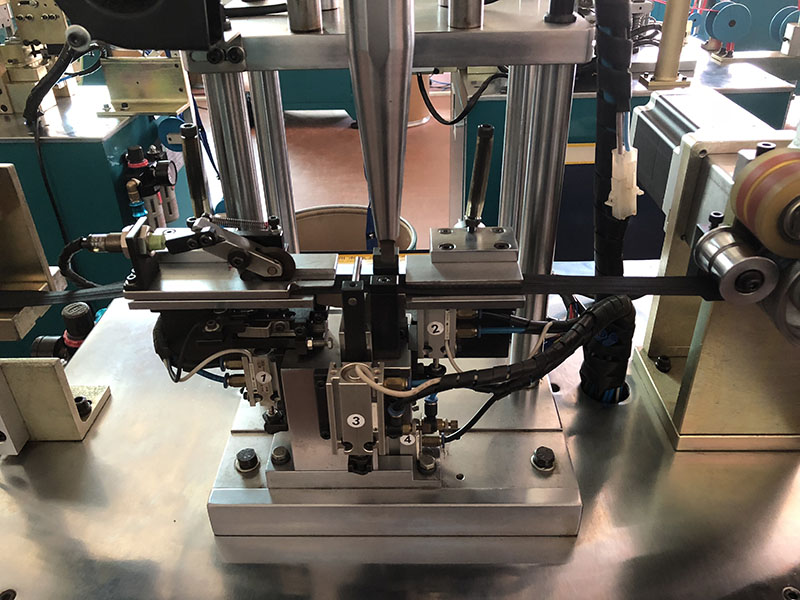

Bottom stop welding mold

Welding zipper teeth as bottom stop

| Style Number | ZY-206N-C |

| Machine Name | Full-automatic Nylon Zipper Bottom Stop Machine (welding teeth) |

| Capicity | 2500PCS/18CM/H |

| Size | #3, #4, #5, #7, #8, #10 |

| Power | 1.60KW |

| Voltage | 220V |

| Machine Measurement (M) | 1.20*0.70*1.85 |

| Net Weight | 163KG |

| Warranty | 1 year |

| After-sales service | Available |

Copyright © 2025 Design by www.zipper-machines.com

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist