BETTER TOUCH BETTER BUSINESS

Contact Sales at Zipper.

ZYZM Zipper Machine Manufacturer-One Stop Solution Service Provider for all kind of Zipper Making Machines.

The selection of a zipper making machine demands careful consideration, given the substantial investment that such machinery entails and the pivotal role that it plays in the overall production process. This article comprehensively outlines the main factors to consider when choosing a zipper making machine, exploring its key components, different types, and the technological features that impact manufacturing efficiency and product quality.

Understanding the Zipper-Making Process

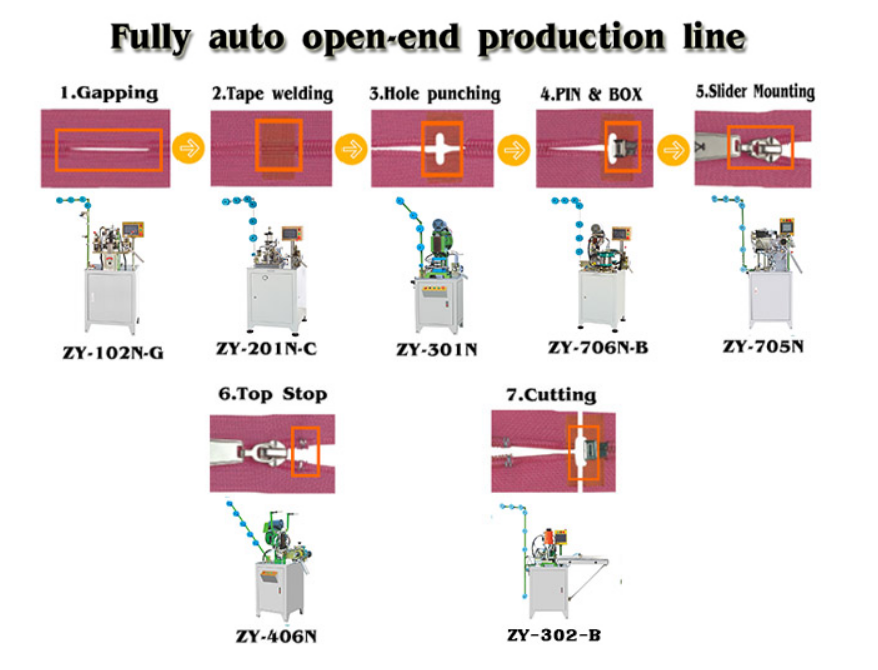

Zipper production comprises several steps, including wire making, chain making, slider mounting, and finished product assembly. A zipper making machine should be capable of handling these steps with precision and speed. The process starts with wire making, where a continuous wire is made from a metal strip. Next, the chain-making machine transforms the wire into zipper teeth. The zipper tape is then attached to these teeth in a weaving process. Finally, the slider is mounted, and the final zipper product is completed.

Four Types of zipper making machines

When it comes to zipper production, the right machinery can make all the difference. Different types of zipper making machines are required to produce different styles of zippers. Here are the four main types of zipper making machines and their applications:

Metal zipper making machine

As the name suggests, these machines are designed to produce metal zippers, which are widely used in jeans, coats, and backpacks, among other items. Metal zipper making machines are adept at creating strong, durable zippers from various metals, including brass, aluminum, and nickel. They are recognized for their robust construction, high speed, and longevity. Though they require a higher upfront investment, their performance and the demand for metal zippers make them worthwhile.

Nylon Zipper Making Machine

This type of machine is specifically engineered for producing nylon zippers, which are lightweight, durable, and corrosion-resistant. Nylon zippers are ubiquitous in various products, including luggage, bags, sportswear, shoes, bedding, and tents. The nylon zipper machine is revered for its easy operation, quick production times, and lower cost compared to its metal counterpart.

Plastic zipper making machine

Plastic zipper machines manufacture zippers from plastic materials such as PVC and polyester, offering a good balance between cost and durability. The resultant plastic zippers are extensively used in clothing, backpacks, and pockets, among other items. This machine type is generally more affordable, making it a popular choice for businesses with tighter budgets. Plastic zipper machines are also easier to maintain, reducing the total cost of ownership over time.

Zipper Machine for Invisible Zippers

These machines are designed to create invisible zippers, which blend seamlessly with the garment, providing an unbroken line that enhances the aesthetic appeal of lady dresses, skirts, and trousers. Invisible zippers are a staple in high-end fashion due to their neat finish. The machine produces these intricate zippers with high precision, speed, and efficiency. Despite being more complex to operate, their superior finish justifies the investment.

Key Considerations for Selecting a zipper making machine

● Production Capacity: The machine's production capacity refers to the number of zippers it can produce within a given time. Higher-capacity machines are more expensive but can meet higher demand, making them suitable for larger operations.

● Operational Efficiency: This refers to the power consumption and manual effort required to operate the machine. Machines with high operational efficiency consume less power and require minimal human intervention, making them more cost-effective in the long run.

● Precision and Consistency: The precision of a zipper making machine refers to the accuracy with which it produces each part of the zipper. Consistency, on the other hand, refers to the ability of the machine to maintain this precision over time. Both factors directly influence the quality of the final product.

● Ease of Operation: Selecting a machine that is user-friendly and straightforward to operate can significantly streamline the production process. An easy-to-operate machine reduces the time and resources spent on training staff, leading to increased productivity and reduced downtime. Moreover, simplicity in operation also minimizes the risk of operator error, which could lead to costly production defects or machine damage.

● Maintenance Requirements: Regular maintenance is crucial for prolonging the lifespan of your machine and ensuring optimal performance. Therefore, consider the frequency and cost of maintenance when selecting a machine.

● Manufacturer’s Reputation: Choosing a machine from a reputable manufacturer is of paramount importance. Not only does it guarantee high-quality machinery built from years of expertise and innovative design, but it also ensures exceptional after-sales service. A reputed manufacturer like ZYZM Zipper Machine Manufacturer stands behind their product, offering comprehensive support and maintenance services to keep your machine in optimal condition.

● Budget: While it's important to invest in a high-quality machine, you also need to balance this with your budget constraints. Remember, the most expensive machine is not necessarily the best for your specific needs.

Advanced Technological Features

Modern zipper making machines are equipped with advanced features that enhance their efficiency, precision, and ease of operation.

Computerized Control: This feature allows for the automation of the zipper production process, reducing manual effort and increasing production speed.

Precision Engineering: This refers to the use of advanced design and manufacturing techniques to ensure the high precision and consistency of the machine.

Integrated Quality Control Systems: These systems automatically check the quality of the zippers produced and detect any defects, reducing the need for manual inspection and ensuring high product quality.

Bottom Line

Are you looking for a reliable, high-quality zipper making machine to bolster your production capabilities and deliver exceptional products? If so, look no further than ZYZM Zipper Machine Manufacturer.

At ZYZM, we pride ourselves on our expertise in the production of a wide range of zipper machines, encompassing metal, nylon, plastic, and invisible zipper machines. Our commitment to the principle of mastering core technology independently, combined with our adoption of international standards in processing technology and methods, sets us apart in the industry.

Whether you're a start-up setting up your first production line or an established enterprise looking to expand your production, we're here to help. Reach out to us today, and let's discuss how ZYZM can drive your business toward unprecedented success.

Let's make the best zippers together with ZYZM! Get in touch with us today and elevate your zipper production to new heights.

Copyright © 2025 Design by www.zipper-machines.com

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist